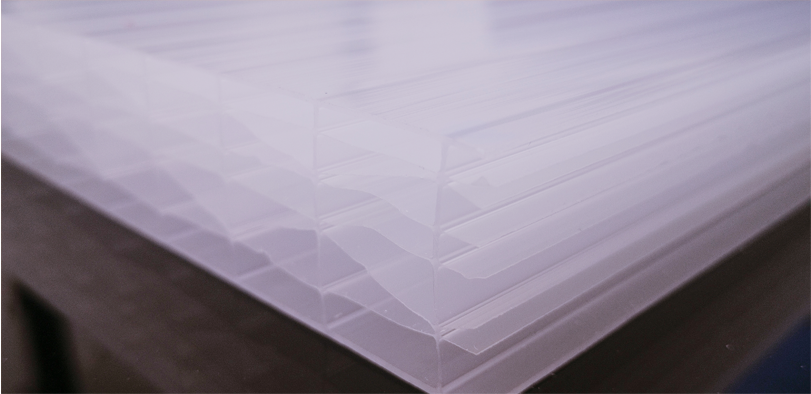

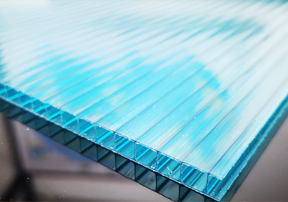

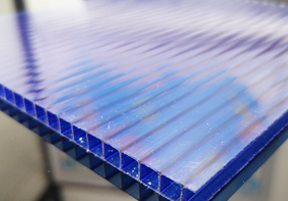

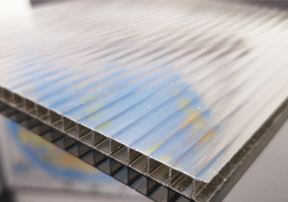

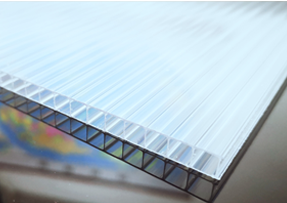

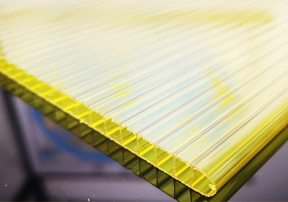

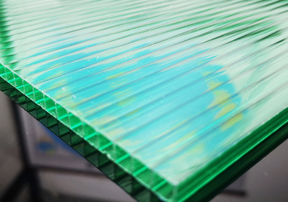

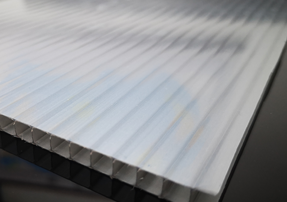

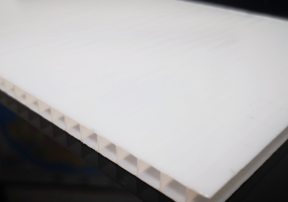

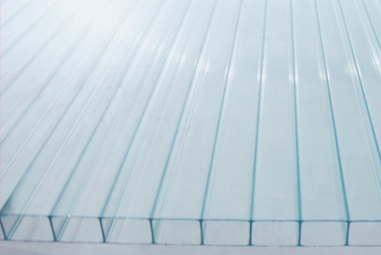

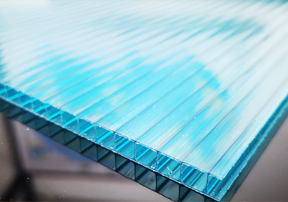

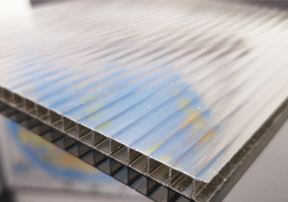

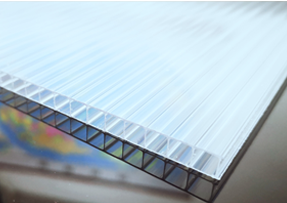

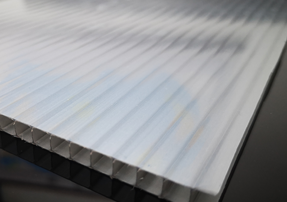

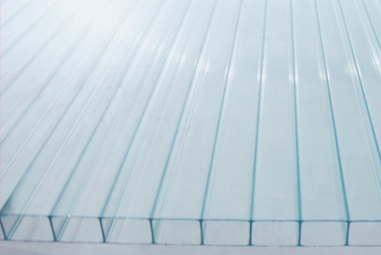

Polycarbonate hollow sheet is engineering Thermoplastics. Extrusion molding through Omipa&Breyer extrusion line.It is with 1UV/2UV layer. It has goods physical and mechanical properties.Weight is only 1/12~1/15 of the same thickness of glass.

|

|

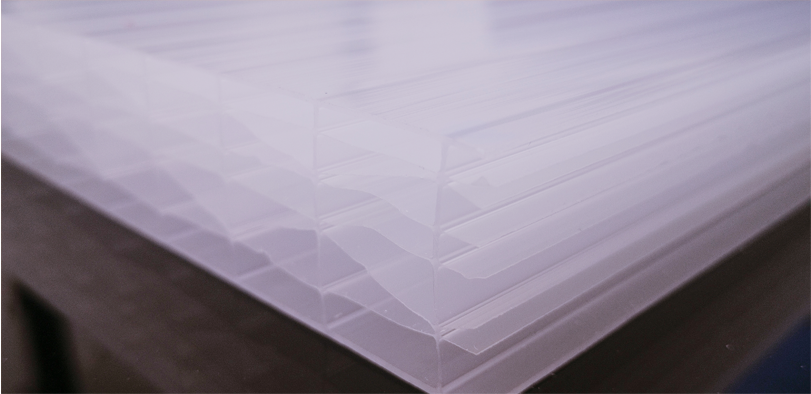

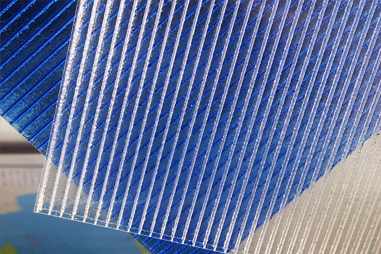

7 WALL D-STRUCTURE HOLLOW SHEET

|

|

| Thicknes(mm) |

Width(mm) |

Length(mm) |

UV(um)

|

Warranty

|

LT%

|

|

22-38mm

|

1220/2100

|

No limited

|

1or2 sides

|

10 years

|

clear(85%)

|

|

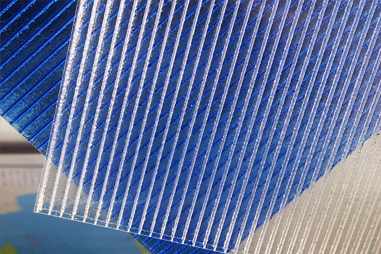

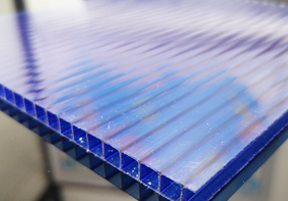

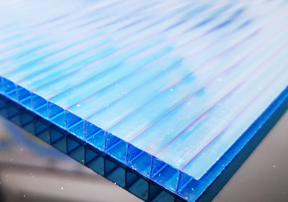

Blue Green

|

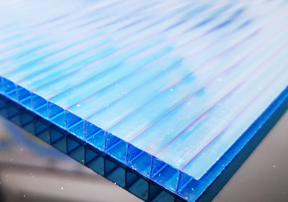

Blue

|

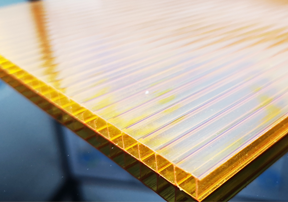

Bronze

|

Clear

|

|

Close edge function

|

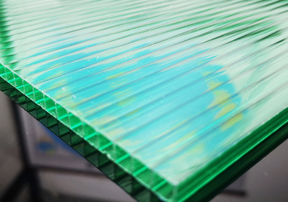

Green

|

Lake Blue

|

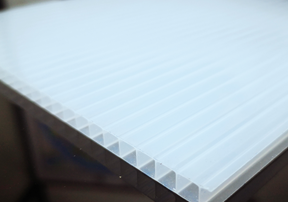

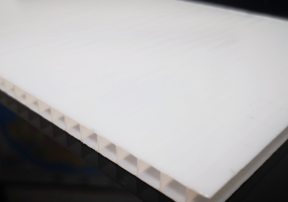

Opal

|

|

Orange

|

Silver

|

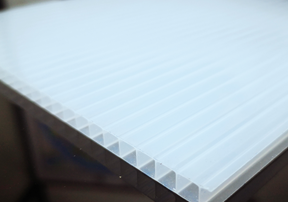

White

|

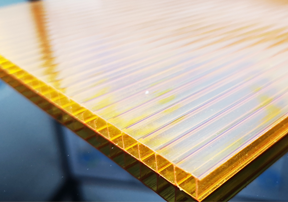

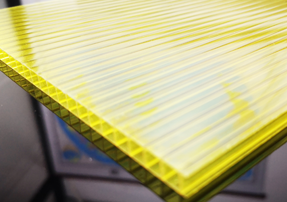

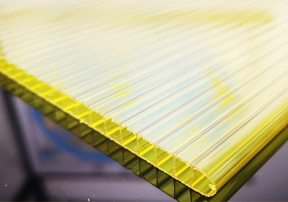

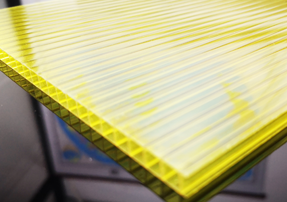

Yellow

|

|

Anti drop for greenhouse

|

Glitter for decoration

|

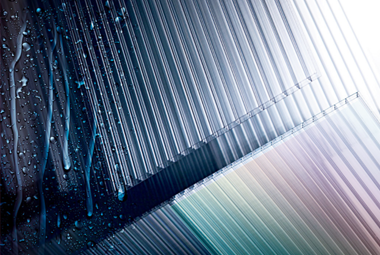

Anti Infrared for roofing

|

|

|

|

|

Performance:

Light weight

High impact strength

High light transmittance

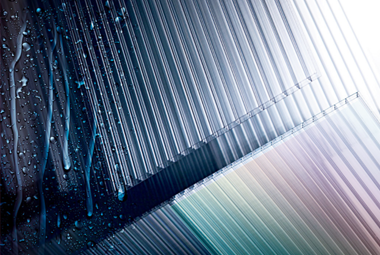

Weather and UV resistant

High thermal insulation performance

Easy to process and install

|

|

|

Application area:

Residential/commercial skylight

Factory building, warehouse lighting roof

Stadium ceiling

Channel/parking shed

Swimming pool top cover

Indoor partition

|

|

|

Property

|

Standard

|

Standard |

Unit

|

Value

|

|

Density

|

ASTM D792

|

|

g/cm3

|

1.2

|

|

Heat Deflection Temperature

Service Temperature Range

|

ASTM D648

|

1.82 MPa

|

OC

OC

|

130

-40 to 120

|

|

Coefficient of Linear Thermal Expansion

|

ASTM D696

|

|

cm/cm OC

|

6.5 X 10-5

|

|

Thermal Conductivity

|

ASTM C177

|

|

W/mK |

0.21

|

|

Tensile Strength at Yield

|

ASTM D638

|

10 mm/min

|

MPa

|

65

|

|

Tensile Strength at Break

|

ASTM D638

|

10 mm/min

|

MPa |

60

|

|

Elongation at YieldMPa

|

ASTM D638

|

10 mm/min

|

%

|

6 |

|

Elongation at Break

|

ASTM D638

|

10 mm/min

|

%

|

>90

|

|

Tensile Modulus of Elasticity

|

ASTM D638

|

1 mm/min

|

MPa

|

2300

|

|

Flexural Strength

|

ASTM D790

|

1.3 mm/min

|

MPa

|

100 |

|

Flexural Modulus

|

ASTM D790

|

1.3 mm/min

|

MPa

|

2600 |

|

Impact Falling Weight (E-50)

|

ISO 6603/1

|

|

J

|

195 |

|

Rockwell Hardness

|

ASTM D785

|

|

R Scale |

125R

|

|

Light Transmission

|

ASTM D1003

|

|

%

|

80

|

|

Haze

|

ASTM D1003

|

|

%

|

<0.5

|

|

Yellowness Index

|

ASTM D1925

|

|

|

<1

|

|